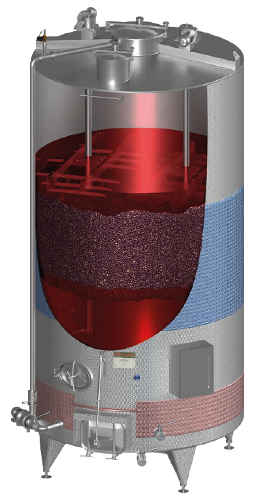

FERMENTATION TANK - SOFT SYSTEM® AUGER

SOFT SYSTEM® offers the possibility of managing the punching down process in a precise and modern way.

The wide range of sizes offered by the Soft System® gives the possibility of making wine with an actual capacity ranging from 25 to 850 hl and represents together with easy-to–use application and functionality, the strength of the system allowing to achieve excellent winemaking results even with small quantities of the product.The Soft System® enhances the tradition of manual punching down in a soft and calibrated way, managing and customizing it according to the types of wine grapes and the desired result: from fresh wine to winemaking and maceration of withering grapes with a high percentage of marc.

The strict temperature control provided by the system lets operate on a broad spectrum of phases. Thus, in refrigeration mode, it allows performing a classical fermentation but also a specific cryomaceration and in heating mode permits to operate with both late/winter as well as malolactic fermentations.

Thanks to the long stroke of the stainless steel augers, the operator can manage and optimise the manner and timing of the various stages of processing.

Punching down process with 1 or 2 augers

With 1-Auger Soft System® the operator can completely plunch down the cap of the marc into the grape must.

The 2-Auger Soft System® allows the operator to act on the cap of the marc in two different ways. First, using the long-stroke stainless steel augers in

an individual and independent way, which let the cap to be overturned and partially broken and its mass to become homogeneous with the release of the amount of carbon dioxide (CO2) in excess (the process

is similar to delestage). Then, acting simultaneously with the long-stroke stainless steel augers and ensuring the complete immersion of the cap into the must,

flavours and colors can be released during the following resurfacing to create an important wine.

The possibility to disassemble the grids makes simple further cleaning operations, thus allowing reuse of the Soft System® as temperature controlled storage tanks.

ADVANTAGES

- Designed to obtain thin layers of marc and extensive contact surfaces between solid and liquid.

- Full functionality already at a 30% capacity.

- The handling system optimises the dissolution of the colouring pigments during the maceration process, operating at the same time at low noise levels.

- Continuous monitoring of temperature, managed through PLC with an intuitive touch screen multilingual interface.

- Possibility to log the historical data of all performed operations, in order to reproduce the desired process.

- Must is processed with customisable working and pausing times

- Equipped with a traditional effective remontage system (pumping over), it helps to obtain total irrigation of the cap ensuring effective inner contact between the marc and the must.

- Allows the extraction of undesired grape seeds from the bottom by the use of special combs (option).

- Compact shape to optimize space in the cellar.