FLASH DETENTE THERMOVINIFICATION

This innovative thermovinification process significantly improves the quality of the wines and adapts the type of wine to consumer requests.

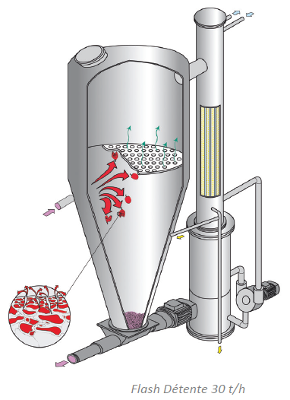

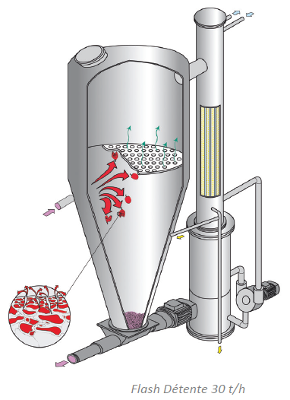

HOW IT WORKS

The 'flash détente' thermovinification process consists of a fast heat treatment, with the grapes brought up to high temperature, followed by immediate cooling by pressure reduction.

1) Heating the grapes: two tools available

- Dynamic coaxial heat exchanger

- Grapes Heating

2) Heating the grapes: two tools available

The heat-treated grapes are fed into the vacuum chamber. This high vacuum chamber causes an almost instantaneous cooling of the

grapes.

The vapour generated is condensed. The condensates and the run-off juices are fed back into the pump.

ADVANTAGES

- Quality:

- Rounder, fatter, fruitier wines

- Stable colour and aromas

- Alters the harmful enzymes (laccase, polyphenol and oxidase)

- The wines obtained are less sensitive to deterioration from oxidation

- The full potential of the grapes is revealed - Cost effectiveness:

- Fewer pumping over, labour saving

- The entire volume of the tank is used

- Strong - and faster - alcoholic fermentation

- Better control of the temperature during fermentation

- Fermentation volumes up 25% with the same amount of energy

- Easier tank drainage (if vinification in liquid phase)

- Better coolant exchange during fermentation - Performance:

- Non-stop operation possible

- Continuous process up to alcoholic fermentation

- Reduced heating costs thanks to greater flexibility in harvesting dates

- Improved cellar capacities to produce new styles of wine or juice

- Optimised cellar with more opportunities for the vinification team

- Fermentation capacity increased by 25% for the same energy input - Comfort:

- PERA programmable automat

- Simple and intuitive tactile interface

USER FRIENDLY PROGRAMMING

The PERA automation and programming allow you to:

- Programme the pressing cycles

- Manage any problems (information about the fault and the proposed solution)

- Save the data and programmes on a USB stick for complete traceability

- Alter the pressing programme in real time

- Control several presses from the same panel.