OAK SCAN

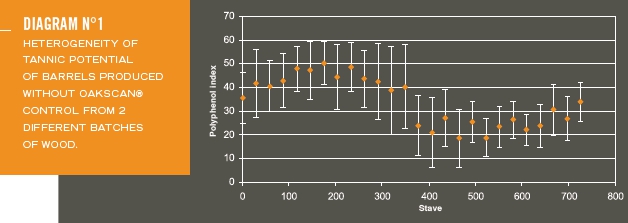

AIM: TO CORRECT THE HETEROGENEOUSNESS OF THE LEVEL OF TANNINS DURING THE BARRELS PRODUCTION

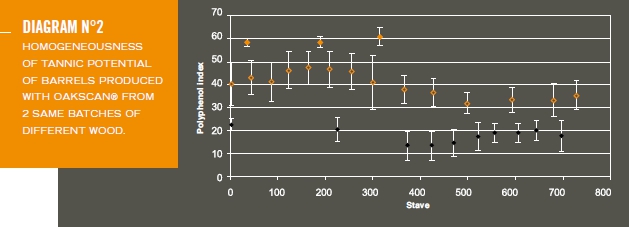

- Radoux OakScan® enables to guarantee that the Radoux Barrels have a homogeneous content of ellagitannins

- It completes the traditional methods of selecting the wood (origin, grain)

- It ensures that the wood used is perfectly suited to the wines objectives.

How does it work ?

Radoux OakScan® is a system of rapid analysis, stave by stave, based on Near Infra red Spectrometry.

Each stave is scanned when entering the production process and is marked with the index of the category of tannic potential to which it belongs.

This polyphenolic index is calculated according to a confidential formula using the OakScan®measurements and estimates the polyphenolic richness

of the wood between indexes 0 and 100. It is a linear combination of the values of the reference chemical indexes (DO280, Folin Ciocalteu and total Ellagitannins).

So from a pallet of rough staves of variable composition (Diagram 1), we obtain three selections of barrels, each of different composition but all of them homogeneous.

A dot represents the average tannic potential of each barrel made form arround 30 staves with no OakScan® grading.

What does it do ?

Radoux OakScan® is currently used to guarantee the homogeneity of tannins in barrels, in addition to the traditional methods of selecting wood. As the staves are being prepared, they are marked and graded into 3 selections :

- Selection 1 (bottom row on the diagram below) Currently, Selection 1 is made up of staves whose polyphenolic index is below 21. It is measured on varietals which are very sensitive to the contribution of tannins from the wood.

- Selection 2 (middle row on the diagram below: The polyphenolic index of Selection 2 is situated between 21 and 56. It is the one which makes up the majority of our production, used for the main varietals which are complete, with richer texture. This selection guarantees a homogeneousness and a reproducibility which has never previously been achieved.

- Selection3 (top row on the diagram below): Selection 3, whose polyphenolic index is between 56 and 67, is specifically used for wines which need the structure brought by the oak during aging.

A dot represents a barrel made from a batch graded with the help of OakScan® of around 30 staves of the same selection.

All the woods over the polyphenolic index of 67 are used for spirits barrels to ensure they have a maximum tannic impact.